+++++++++++++++++++++++++++++++++++++++++++++++++++

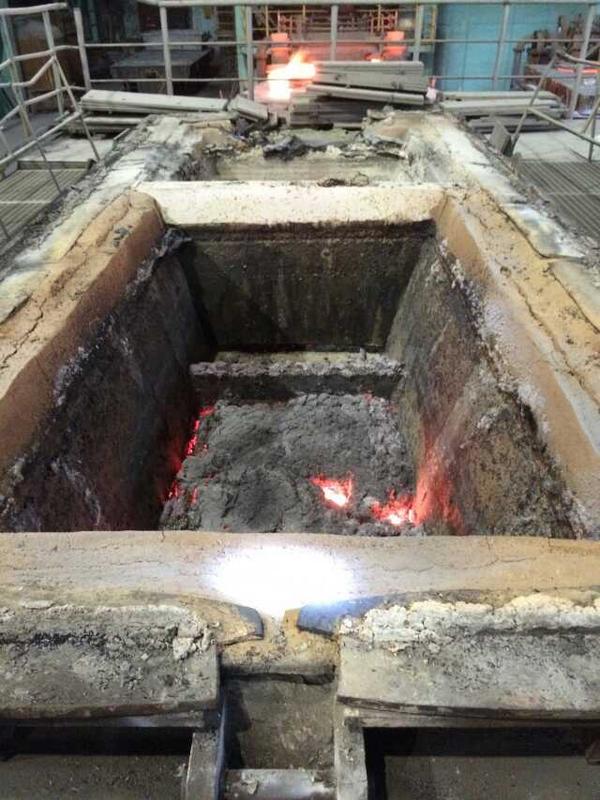

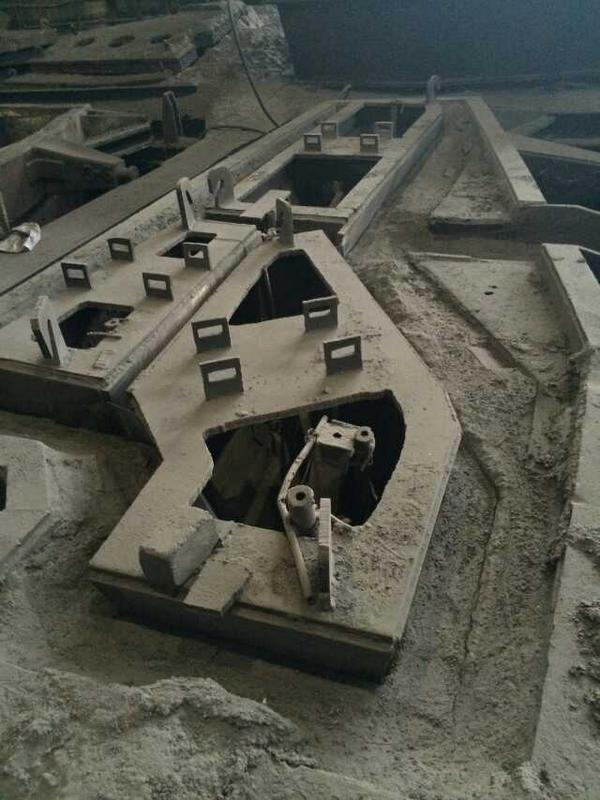

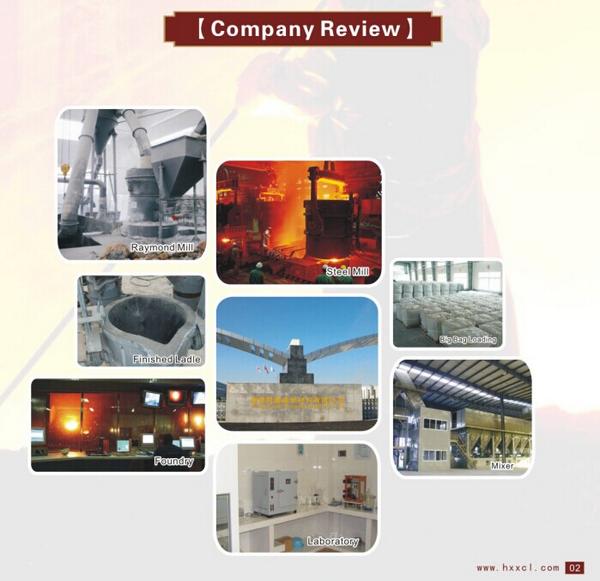

Your reliable partner for refractory solutions!

Xiangtan Hexinsheng New Material Co., Ltd

Tel: +86 731 5559 9698 Fax: +86 731 5559 9697

http://www.hxxcl.com

http://hxxcl.en.alibaba.com/

Carmen Tse

Email: carmen@hxxcl.com

Skype: effi_xie Cell #: 86-189-7322-9620

.jpg)

.jpg)

.jpg)

.jpg)